2025-10-11

LCD modules are widely used in industrial control, medical devices, smart homes, and other fields due to their low power consumption, high reliability, and cost advantages. The choice of interface directly impacts system design complexity, performance, and cost. This article provides an in-depth analysis of the main interface types for monochrome LCD modules and offers practical selection strategies.

I. LCD Module Interface Types

1. Parallel Interface LCD: Traditional & Efficient Communication

The parallel interface is the most classic type for monochrome LCD modules, primarily including the 8080 mode and 6800 mode.

8080 Parallel Interface (Intel Bus Standard) Signal Lines:

Data Lines: D0-D7 (8-bit) or D0-D15 (16-bit)

Control Lines: CS (Chip Select), WR (Write Enable), RD (Read Enable)

Address/Command Select: DC (Data/Command Select)

Reset Line: RST (Hardware Reset)

6800 Parallel Interface (Motorola Bus Standard) differs by:

Using an E (Enable) signal instead of WR/RD.

Parallel Interface Advantages: High data transfer rate, high refresh rate, suitable for large-size or high-resolution displays.

Parallel Interface Disadvantages: Occupies many MCU pins, complex PCB routing.

2. Serial Interfaces: Pin-Saving Solutions

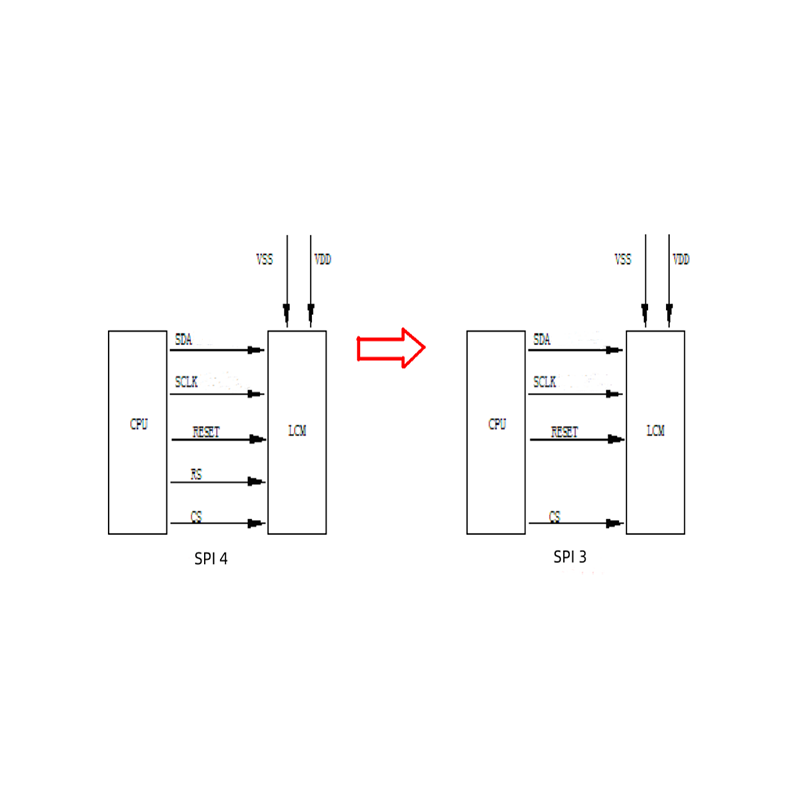

SPI Interface (Serial Peripheral Interface):

Basic 4-wire: SCK (Clock), MOSI (Master Out Slave In), MISO (Master In Slave Out), CS (Chip Select)

3-wire simplified version: MISO can be omitted for write-only applications.

Speed: Typically up to 10-50MHz, suitable for small to medium-sized dot matrix displays.

I2C Interface (Inter-Integrated Circuit):

Two-wire: SDA (Serial Data), SCL (Serial Clock)

Multi-device support: Multiple LCD modules can be connected on the same bus.

Speed: Standard mode 100kHz, Fast mode 400kHz.

Serial Interface Advantages: Significantly save MCU pins, simple routing, smaller PCB area.

Serial Interface Disadvantages: Lower transfer speed, relatively complex protocol.

Although serial interfaces save pins, their data transfer speed is lower than parallel interfaces. Selection requires balancing pin resources against refresh rate requirements.

II. Key Factors for Interface Selection

1. Display Content & Refresh Rate Requirements

Segment Display: Small data volume, low speed requirement -> Choose I2C or SPI.

Character Display: Moderate data volume, periodic updates -> Choose SPI or simple parallel.

Graphic Dot Matrix: Large data volume, requires high refresh rate -> Choose parallel interface.

2. Processor Resources & Performance Matching

Low-end MCUs (e.g., 8051, low-end ARM Cortex-M0):

Prefer SPI or I2C interfaces to avoid using too many GPIOs.

Consider the MCU’s hardware peripheral support; prioritize models with hardware SPI/I2C.

Mid-to-High-end MCUs (e.g., ARM Cortex-M3/M4):

Can choose either parallel or serial interfaces based on requirements.

Parallel interfaces can utilize FSMC (Flexible Static Memory Controller) for improved efficiency.

III. Practical Design Tips & Considerations

1. Interface Level Matching: Ensure the LCD module’s interface logic levels are compatible with the MCU. Some modules are not 5V tolerant; direct connection may damage the device.

2. Reset Timing Control: Correct reset timing is crucial for stable module operation. Maintain a sufficiently long reset pulse width after power-on.

3. Backlight Drive Circuit: Different backlight types require different drive circuits. Consider current-limiting resistors for LED backlights.

4. PCB Space Constraints:

Prefer serial interfaces for compact designs to reduce trace count.

Parallel interfaces can be considered for multi-layer boards, utilizing inter-layer routing.

5. Signal Integrity:

Serial interfaces have advantages for long-distance transmission.

High-speed parallel interfaces require matched termination resistors and careful timing analysis.

Power Supply Filtering: Add decoupling capacitors to each module power pin.

6. Cost Factors

Direct Cost:

Parallel: More pins, higher connector cost.

Serial: Fewer pins, lower connector cost.

Indirect Cost:

Development Difficulty: Software implementation for serial interfaces is relatively more complex.

Maintenance Cost: Parallel interfaces have a relatively higher hardware failure rate.

IV. Typical Case Analysis

Case 1: Smart Meter Display

Requirements: Segment display, slow data updates, low power.

MCU: Low-power 8-bit microcontroller, limited GPIO.

Choice: I2C interface segment LCD module.

Reason: Maximizes pin savings, matches power requirements, low cost.

Case 2: Industrial HMI (Human-Machine Interface)

Requirements: 240×128 dot matrix, real-time data refresh, strong noise immunity.

MCU: ARM Cortex-M4, sufficient resources.

Choice: 8080 parallel interface graphic dot matrix module.

Reason: High refresh rate, good stability, straightforward development.

Case 3: Portable Medical Device

Requirements: 160×160 dot matrix, medium refresh rate, compact design.

MCU: ARM Cortex-M3, limited pin count.

Choice: SPI interface dot matrix module.

Reason: Balances performance and size, simple and reliable routing.